Electrical wire ties offer a quick and trusty solution to maintain electrical wiring in order. Constructed of nylon, they come in diverse sizes to accommodate diverse wire-gauge requirements. Along with bundling cables, they further ensure an orderly structure and secure them to built-up surfaces. By utilizing these ties, the risk of electrical shorts and fire hazards caused by open wiring are minimized, allowing an organized and safe electrical system.

Electrical wiring applications have long relied on the convenience of wire ties to keep cables and other wiring secure. From cars to homes, businesses to appliances and computers, these tried-and-true ties are used to bundle multiple wires together, offering an easy and reliable way to ensure a neat and organised setup.

Wire ties, coming in all shapes and shades, can be composed of multiple materials to choose from. The most popular choice is nylon, but you may also occasionally spot stainless steel and vinyl. The size should be appropriate for the wire you are wanting to secure; usually 4-6 inches is a good rule of thumb, although there are bigger options if your wiring is thicker.

When selecting the appropriate fastening solution for a wiring project, make sure that it is rated for the voltage it will be exposed to. Check that its voltage rating is greater than the maximum voltage of the project to prevent the tie or strap from fracturing or warping due to force. Additionally, be sure to determine the type of wire it needs to secure – as they all require different styles and sizes of tying mechanisms.

To ensure proper installation, the wires need to be bundled together with the tie tightly positioned in the core. Pull it tight until there’s no chance of it slipping free and damaging the wiring, but avoid over-tightening it. After that, make sure to fasten it firmly to its mounting surface; a loose attachment could lead to a short.

To avoid electrical shorts, there must be appropriate spacing between multiple wire ties. If needed, a larger tie can be used to bind the other ties together and minimize the gap between them.

Wire ties are an essential piece in any wiring endeavor, serving as a fast and efficient way of sorting and securing wires. Economically priced and designed with simplicity in mind, they can lower the chances of electrical hazards such as fires arising from exposed wires. For optimal effectiveness, the wire tie size and rating must match the voltage of the wiring job. Additionally, when placing multiple ties, spacing them adequately helps guarantee safety and protection for the entirety of the wiring endeavor.

Recently, the application of electrical wire ties has taken off as a popular solution for structuring and controlling electrical wiring. Electrical wire ties are amazingly versatile, spanning from protecting and tidying up wiring in cars to putting wires into order in a home or workplace.

Nylon and polyester wire ties are reliable and versatile fastening solutions, available in an array of sizes, colors, and varieties. Not only do their strong and tough characteristics provide lasting durability, but their adjustable malleability guarantees that they can be flexibly arranged even in the tightest of spaces without damaging the wires.

With wire ties available in various lengths, from 4 inches up to 24 inches, there is sure to be a size suitable for most projects. The ‘standard’ wire ties feature an integrated pawl, which secures the tie once it is wrapped around the bundle of wires. This makes them ideal for a variety of applications.

If you are in need of a secure and organized wiring solution, look no further than the standard wire tie. The self-locking variety boasts a ratchet system that guarantees it stays firmly in position, and its accidental release is practically impossible. On the other hand, releasable wire ties present the advantage of being easily detached and reused, a desirable asset when adjustments or changes need to be made to wiring.

An often helpful solution for tucking away wires in a tight spot is using wire ties. Whether it be in a wall, ceiling, or anywhere else where wires need to be concealed, these ties are flexible enough to be put precisely into place without the risk of damaging the cables in any way.

Wire ties provide an easy, economical way for electricians to safeguard and structure their wiring. Available in a broad variety of shapes, sizes, and colors, wire ties are an adaptable solution for DIY home jobs and more complex auto sound setups alike. Incorporating these ties into your project guarantees protection and order in your wiring arrangement.

Related Product

Garden Wire

Product information: The garden shingling is made of pvc plastic and high-quality galvanized iron wire, which is 3 to 4 times faster than any material, and the buckle is loose, the […]

PVC Coated Wire

PVC coated wire, also called plastic coated wire, after high temperature dissolution cooled solid PVC particles uniformly wrapped in high-quality black iron wire and galvanized wi […]

Cutting Wire

Product Description: Product Name Cutting Wire Zinc Coating 30-70g Place of Origin Chinese mainland Tensile Strength 33-50kg/mm2 Material Electro galvanizedHot dipped galvan […]

Reel Wire Tool

Product information: Specification of Aluminum Tie Wire Reel Material Plastic & Aluminum Weight 1.95LBS Application Binding Wire MOQ 1000pcs Sample Free Package 5PCS/CARTON &nb […]

Tie Wire

Production Process of rebar tie wire : Steel rod coil — Wire Drawing — Wire Annealing–Rust Removing–Acid Washing– Boiling– Drying– Zinc Feeding– Wire Coiling. Wires Type 1.Galvaniz […]

Double Loop Tie Wire

Double loop tie wire material Product Information: Wire diam. 0.5mm—2.0mm Finishes Black Annealed. Galvanized Annealed, Coppered, PVC coated, Stainless steel Wire gauge BWG6 […]

U Type Wire

Product information: Product Name Scaffolding Packing Galvanized Tie Wire Cuttings U Type Binding Wire Material Electro galvanized,hot dipped galvanized,black annealed,PVC coated W […]

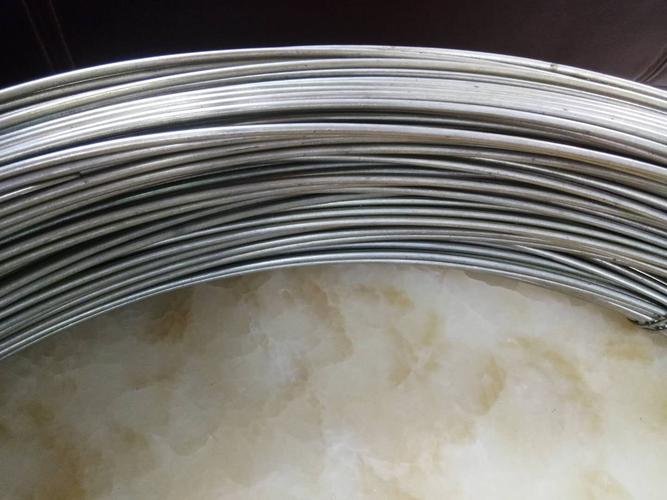

Galvanized Wire

Product information: Product Name Galvanized Wire Package 5kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside 25kgs/roll, pp film inside and hassian […]

Black Annealed Wire

Product Description: Product name Black Annealed Wire MOQ: No Material Q195,Q235 Delivery time: 20days after payment Surface annealed or as your request Payment terms: T/T,L/C We […]

Post time: 2023-07-19