No matter what type of jewelry you are creating, bead stringing wire is an invaluable tool. From bracelets and necklaces, to intricate and unique designs, bead stringing wire is a go-to for many jewelry-makers. It is important to know how to correctly tie of the ends of the wire to guarantee that your beautiful pieces last. This article will instruct you through the step-by-step process of tying off bead stringing wire, so that your creations can withstand the test of time.

After deciding on the size of your jewelry piece, you’ll need to cut a particular length of wire. Aim for 10-15 inches above the desired measurement as this will provide ample space for designing and tying off the ends. Having your item neatly cut, it’s simply a matter of stringing the beads and completing your masterpiece.

When you’ve finished stringing your beads together, tie off the ends of the thread by fashioning a loop at each end. Firmly hold the conduit in one hand and with your other, form a sizable loop with your thumb and forefinger. This loop should tightly secure your beads in place but wide enough to string them through.

To keep your beads safely secured, grasp one end of the wire with a steady hand and wrap it around the loop a few rotations. Pull the conclusion of the wire through the loop, make sure it’s taut and the loop is securely closed. Doing so ensures your beads don’t shift or slip off the wire.

Now it’s time to remove the spare wire. Snip the end of the wire closest to the loop to make a neat and orderly finish on your jewelry.

After you have created and trimmed the wire, it is time to add the clasp for extra security. Simply take the loose end of the wire and guide it through the clasp. Using your pliers, firmly close the clasp, which will lock it in place. Congratulations! You have finished crafting your very own piece of jewelry and can quickly style it with your favorite outfit.

With a bit of practice and these instructions, your jewelry will be secure and long-lasting. You now have the skills needed to produce stunning, one-of-a-kind pieces. Sewing the ends of such bead stringing wire is a small effort that rewards you with mighty results!

For jewelry and other craft projects, stringing a selection of beads can be a fun and satisfying endeavour. Although it requires special materials, such as beading wire, which is available in multiple colors and materials, the outcome of your work still depends on the proper type of wire chosen for the occasion. Also ascertainable is the necessity to tie-off your beading wire correctly to guarantee security for the beads. In this post, we are going to detail how to do just that, so your project can reach its end with assuredness.

To get started on tying off your beading wire, start by snipping it to the exact size you want. Make sure that the tool you use is sharp and effective – like a pair of scissors or wire cutters – to keep the ends from fraying. Then, fasten the cut beading wire to the clasp or other foundational pieces that will hold all of your beads in place. Depending on which pieces you choose, there are various effective ways to go about this.

When needing to firmly secure beading wire, a crimp bead is the ideal solution. This specialized bead is perfectly designed for the purpose, and can provide a dependable connection to any clasp or finding. To utilize one’s benefits, begin by routing the beading wire through the desired element. Then, threading the wire through the crimp bead, use round-nose pliers to press it snugly against the wire. To finish, employ flat-nose pliers to flatten the bead and produce a reliable bond between the parts.

Using a crimp cover is a neat way to finish off beading wire. Designed to snugly fit over a crimp bead, crimp covers offer an aesthetically pleasing end-result. To apply one, thread the wire through the clasp or finding. Keep going and run the wire through the crimp bead and press down with round-nosed pliers. All that’s left is to pop the cover on and clamp it down with flat-nose pliers. After these few simple steps, your beading wire will be looking great, securely fastened off.

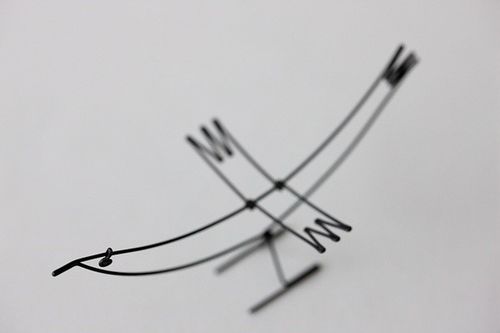

Crafters and jewelry enthusiasts have the option of tying off beading wire with a wire loop. To produce this loop, one should first cut the beading wire to their desired length and thread it through the clasp or finding. Afterward, using round-nose pliers create an elegant curve in the wire. Finally, secure the loop’s shape with flat-nose pliers for a sturdy connection – useful if you’re dealing with large beads!

To finish off your beading wire and give it a professional look, you can make a wire knot. Start by cutting the beading wire down to the size you need. Pass it through the clasp or finding, creating a loop with round-nose pliers. Finish with a knot, pinch the two ends together using flat-nose pliers. This way, you’ll create a secure connection and your wires won’t unravel.

For a successful art project, it is essential to ensure that the wire is suitably attached to the clasp or other connector. This will not only make the beading stay firm but also give your craft an outstanding spick-and-span look. With a bit of practice, you will soon become a pro at concluding your beading wire.

Related Product

PVC Coated Wire

PVC coated wire, also called plastic coated wire, after high temperature dissolution cooled solid PVC particles uniformly wrapped in high-quality black iron wire and galvanized wi […]

Cutting Wire

Product Description: Product Name Cutting Wire Zinc Coating 30-70g Place of Origin Chinese mainland Tensile Strength 33-50kg/mm2 Material Electro galvanizedHot dipped galvan […]

Black Annealed Wire

Product Description: Product name Black Annealed Wire MOQ: No Material Q195,Q235 Delivery time: 20days after payment Surface annealed or as your request Payment terms: T/T,L/C We […]

Twister Tool

Handle Twister tool,plastic handle: Weight: 0.4kg Color: Black, blue,yellow ,red etc Material: Carbon Steel Plastic Handle Wire Tie / Tying Hook Tool Twister Wooden Handle […]

Galvanized Wire

Product information: Product Name Galvanized Wire Package 5kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside 25kgs/roll, pp film inside and hassian […]

Double Loop Tie Wire

Double loop tie wire material Product Information: Wire diam. 0.5mm—2.0mm Finishes Black Annealed. Galvanized Annealed, Coppered, PVC coated, Stainless steel Wire gauge BWG6 […]

Garden Wire

Product information: The garden shingling is made of pvc plastic and high-quality galvanized iron wire, which is 3 to 4 times faster than any material, and the buckle is loose, the […]

U Type Wire

Product information: Product Name Scaffolding Packing Galvanized Tie Wire Cuttings U Type Binding Wire Material Electro galvanized,hot dipped galvanized,black annealed,PVC coated W […]

Reel Wire Tool

Product information: Specification of Aluminum Tie Wire Reel Material Plastic & Aluminum Weight 1.95LBS Application Binding Wire MOQ 1000pcs Sample Free Package 5PCS/CARTON &nb […]

Post time: 2023-08-10