If quick and efficient jobs are what you are looking for, then tie wire wheels are an absolute must-have for your toolbox. From slicing through metal sheets to finessing stubbornly tightened bolts and nuts, these small but mighty tools are sure to make things easier.

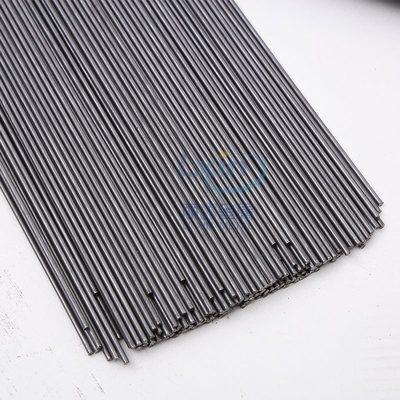

Constructed of metal rods and wire strands twisted together, a tie wire wheel is a circular cutting tool that is widely-deployed in numerous industrial settings. From auto body shops to construction sites, this highly effective wheel can slice through metal and other arduous materials with tremendous ease.

Forged from metal rods and wire strands, the wire wheel stands tall with two comprehensive components: the blade and wheel. Interwoven and secured to the wheel, often built of sturdy steel or aluminium, the blade enables a tremendously resilient tool fit to gallantly slice through heavy-duty material.

Using a wire wheel with a tie requires concentrated safety precautions. Appropriate protective clothing, such as gloves and eye protection, must be worn while operating the instrument. Additionally, careful attention is needed to confirm the secure fastening of the wheel and its handle, or else serious risk may ensue.

When using a tie wire wheel, extra precaution must be taken to guarantee the desired material is firmly held in place. This essential measure proactively avoids accidents caused by the blade sliding off. Additionally, the material should not be excessively thick as that could prevent the wheel from effectively slicing it.

It is essential to use the proper approach when using a tie wire wheel to ensure that the tool doesn’t get caught within the material and causes it to snap. Begin by working outwards, gradually traversing inwards. This will guarantee that any eventual mishaps may be avoided.

Harboring a tie wire wheel in your toolbox proves to be a useful asset, capable of tackling a multitude of tasks varying from metal cutting to tightening screws and nuts. To guarantee safety, it is vital to take precautionary steps such as putting on safety items like gloves and eye protection and firmly attaching the wheel to its handle. Also, ensure that the material being cut is securely held and not too thick for the blade to process. When used with the right care, tie wire wheels can aid in completing tasks rapidly and competently.

For applications requiring supreme strength and durability, tie wire wheels are the perfect choice. Crafted from several pieces of steel wire that have been twisted together, such wheels can move heavy items and materials, as well as transport large objects – no challenge is too great for their unflinching capability. Time and time again, tie wire wheels have proven themselves to be reliable in even the toughest conditions, ensuring they remain a go-to cornerstone of many industrial applications.

Tie wire wheels have countless applications in industries ranging from engineering and construction through to manufacturing and agriculture. They provide a secure transportation for smaller items such as materials, while being strong enough to shift large items like pallets and crates. For farmers, these wheels are especially vital for moving heavy items, such as feed bags and hay bales, from one area to another. In this way, they help to create a safe, efficient method of transferring goods in many different industries.

Wheels crafted with tie wire come in a range of materials, including steel and aluminum. Steel is a favored choice due to its unrelenting strength and resilience, while aluminum is popular for its lightweight build and convenient maneuvrability. Additionally, the wheels are typically sealed with a defensive coating like zinc or chrome, that reduces the effects of hostile elements.

Selecting a tie wire wheel necessitates evaluating its size, weight, and load capacity. The scale of the wheel forms the basis for its capability to bear weight; the load capacity, in turn, defines how much matter it can shift. If an inadequate wheel is put to task, it may damage the subject material. Further, one must consider the natural conditions in which it will be employed – whether that be a setting where corrosion protection or temperature resilience is called for.

Before employing tie wire wheels, adhering to safety measures is imperative. Inspect the wheels to ascertain they are in acceptable condition and all contraptions are fastened properly. Furthermore, it is essential to guarantee that the wheel is correctly installed and attached to whatever surface it will be used on.

Tie wire wheels have earned their place as an indispensible asset on countless worksites. Boasting strength and longevity, they can shrug off difficult conditions and everyday workloads with effortless ease, making them an ideal choice to transport heavy objects with ease. Through maintenance and thoughtful handling, these incredibly practical wheels are designed to withstand years of use and never fail to provide dependable convenience.

Related Product

Twister Tool

Handle Twister tool,plastic handle: Weight: 0.4kg Color: Black, blue,yellow ,red etc Material: Carbon Steel Plastic Handle Wire Tie / Tying Hook Tool Twister Wooden Handle […]

U Type Wire

Product information: Product Name Scaffolding Packing Galvanized Tie Wire Cuttings U Type Binding Wire Material Electro galvanized,hot dipped galvanized,black annealed,PVC coated W […]

Galvanized Wire

Product information: Product Name Galvanized Wire Package 5kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside 25kgs/roll, pp film inside and hassian […]

Reel Wire Tool

Product information: Specification of Aluminum Tie Wire Reel Material Plastic & Aluminum Weight 1.95LBS Application Binding Wire MOQ 1000pcs Sample Free Package 5PCS/CARTON &nb […]

Tie Wire

Production Process of rebar tie wire : Steel rod coil — Wire Drawing — Wire Annealing–Rust Removing–Acid Washing– Boiling– Drying– Zinc Feeding– Wire Coiling. Wires Type 1.Galvaniz […]

Garden Wire

Product information: The garden shingling is made of pvc plastic and high-quality galvanized iron wire, which is 3 to 4 times faster than any material, and the buckle is loose, the […]

Black Annealed Wire

Product Description: Product name Black Annealed Wire MOQ: No Material Q195,Q235 Delivery time: 20days after payment Surface annealed or as your request Payment terms: T/T,L/C We […]

Double Loop Tie Wire

Double loop tie wire material Product Information: Wire diam. 0.5mm—2.0mm Finishes Black Annealed. Galvanized Annealed, Coppered, PVC coated, Stainless steel Wire gauge BWG6 […]

Cutting Wire

Product Description: Product Name Cutting Wire Zinc Coating 30-70g Place of Origin Chinese mainland Tensile Strength 33-50kg/mm2 Material Electro galvanizedHot dipped galvan […]

Post time: 2023-08-01